What is shingled magnetic recording (SMR)? | Definition from TechTarget

What is shingled magnetic recording (SMR)?

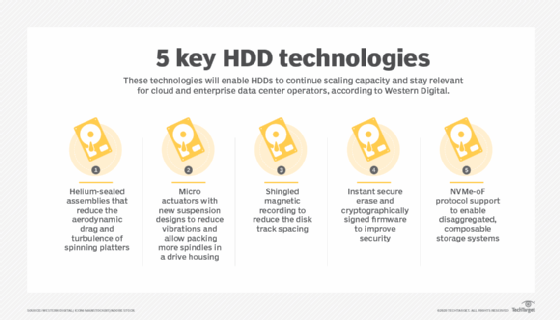

Shingled magnetic recording (SMR) is a technique for writing data to a hard disk drive (HDD) whereby the data tracks partially overlap to increase the areal density and overall storage capacity per disk.

In SMR HDDs, the term derives from the manner in which shingles are installed on a roof, with portions of the shingles overlapping each other. Overlapping shingles on a roof increases the number that can be installed, which helps seal the building and keep it watertight from inclement weather.

Applying a similar principle to HDDs means overlapping data tracks in an HDD platter, which is the circular magnetic plate on which data is stored. By shingling the tracks, the data is written on them sequentially. Also, the gaps between the tracks are removed, which helps to increase the drive’s areal density. Because more data tracks can be placed on each magnetic surface, the drive’s overall storage capacity increases.

How do shingled magnetic recording drives work?

SMR HDDs overcome the physical limitation of conventional hard drives. The head is relatively wide, and the SMR drive writes the data tracks strictly sequentially in overlapping fashion. The write width and pole-tip width can be much larger than the resulting final track width, or shingled width.

As a result, the system can use a relatively strong writer to create very narrow tracks and achieve greater data density. Since the data in the newly written track overlaps the data in the adjoining track, updates of individual tracks or sectors might require a read and rewrite of an entire band of shingled tracks.

The SMR disk’s tracks need sharp definition on only the edge that is overlapping the previously written adjacent track. Design engineers thus have the freedom to make the critical edge sharper, allowing the shingled tracks to be placed closer together.

Pros and cons of shingled magnetic recording drives

Layering an HDD platter’s tracks on top of each other increases the tracks per inch, which increases the HDD’s capacity without increasing its physical footprint. Due to the capacity gains, an SMR disk drive works optimally for long sequential writes, when the system writes data continuously to the disk. Examples of sequential writes include backups and archives of data. High-performance sequential workloads can also benefit from SMR technology.

Furthermore, the larger write head in SMR drives can effectively write on the media while ensuring the data’s readability and the drive’s stability. SMR also provides random-read capability, allowing for rapid data access.

One drawback of SMR drives is that regardless of how SMR is implemented, the data must be written sequentially; since the tracks are overlapping, the larger write head could potentially destroy data. This issue can be mitigated by placing recording gaps between fixed-capacity zones, or groups or bands of overlapping tracks. These gaps prevent the write head from overwriting data on the same platter surface.

Another issue is that random modifications to pre-written data on the disk can potentially cause inconsistent write throughput performance, but manufacturers have enhanced the SMR design and developed firmware and software improvements to address the issue. Also, if the operating system does not support sequential writes, a management or translation layer is necessary to convert random writes to sequential writes, prevent data overwrites and maintain data integrity.

Shingled magnetic recording vs. perpendicular magnetic recording

Perpendicular magnetic recording (PMR) HDDs pack narrow concentric tracks in parallel as closely as possible to increase areal density. There are gaps between the tracks to account for the drive’s track misregistration budget. Due to these gaps, some parts of the drive platter’s surface are not fully utilized, resulting in lower available capacity to store data.

Also, with PMR, the recorded signal must sharply diminish on both sides of a newly written track in order to leave a gap between tracks; that task becomes more difficult as tracks get narrower and closer together. Manufacturers have to shrink the width of the magnetic poles on the write element in the read/write head to accommodate the narrow writing. The constriction of the poles has the unwanted consequence of reducing the strength of the magnetic field to write data to the disk.

In SMR drives, the gaps are removed by writing the tracks in an overlapping and sequential manner to form a shingled pattern that allows for more tracks to be placed on the platter, increasing the drive’s areal density and data capacity.

Another difference between SMR and PMR drives is that in SMR drives, direct modification of data sectors is not permitted. This is because modifying one sector requires the entire zone to be rewritten, as that sector could be under another shingle.

Finally, SMR drives feature a larger write head compared with conventional PMR drives, which helps to produce a stronger magnetic field and minimize the problem of a low energy barrier. Such a barrier, common in PMR drives, flips bits on the drive’s media — also called flipped magnetization — reducing its data integrity. The larger head in SMR drives means a larger write field, which prevents flipped magnetization and thus maintains high data integrity and readability.

See why the future of data storage must handle heavy volume and check out the top data storage trends for the coming year.